Product Description

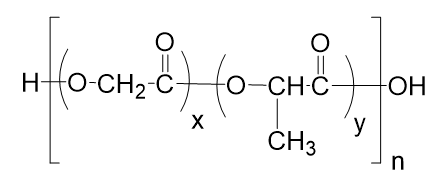

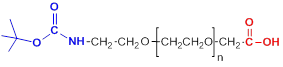

Acid capped poly(D,L-lactide-co-glycolide) (PLGA-acid, PLGA-COOH, PLGA acid terminated, D,L-LA/GA=50:50 or 75:25) can be used to prepare nanoparticles, which can be further modified by amine-reactive entities. PLGA-COOH can be used to prepare polymer-drug conjugates.

Poly (lactide-co-glycolide) (PLGA) is one of the most effective biodegradable polymeric nanoparticles (NPs). It has been approved by the US FDA to use in drug delivery systems due to controlled and sustained- release properties, low toxicity, and biocompatibility with tissue and cells.

Poly(lactide-co-glycolide) (PLGA) is an ubiquitous biodegradable polymer. It is typically used to fabricate medical devices that predictably degrade over months in physiological conditions. The well-researched release profile also allows for drug-release functionalization with calculable results. Depending on the ratio of lactide to glycolide used for the polymerization, different forms of PLGA can be obtained: these are usually identified in regard to the molar ratio of the monomers used (e.g. PLGA 75:25 identifies a copolymer whose composition is 75% lactic acid and 25% glycolic acid). The crystallinity of PLGAs will vary from fully amorphous to fully crystalline depending on block structure and molar ratio. PLGAs typically show a glass transition temperature in the range of 40-60 °C. PLGA can be dissolved by a wide range of solvents, depending on composition. Higher lactide polymers can be dissolved using chlorinated solvents whereas higher glycolide materials will require the use of fluorinated solvents such as HFIP.

Owing to its extensive history, PLGA is one of the most understood and affordable biodegradable polymers for medical devices today. PLGA has been successful as a biodegradable polymer because it undergoes hydrolysis in the body to produce the original monomers, lactic acid and glycolic acid. These two monomers under normal physiological conditions, are by-products of various metabolic pathways in the body.